MORTAR:

Mortars must be put in the whole slab, using trowel teeth. If there is not a previous study about the supplier we must test it before use. When we use resin, because of its high cost we can put a thin lay of resin in the whole slab and then put a bigger amount in a few point. This avoids a change in the colour between different places in the slab.

ANCHORAGE:

Anchors will be used in the following cases:

1. The considered maximum high without the use of anchors in 3 meter high.

2. Big tiles must be fixed with anchors, placing at least two ribs at the base and two in the top of each piece spaced at a distance no greater than 400 mm. For a thickness form 10 mm to 20 mm the use of anchorage can be avoided, after that thickness the use of anchors is recommended. However, it depends on the country; in some countries depends on the thickness, but in other ones depends on the size of the tiles: over 3600 cm2 (60x60 cm) the use of anchors is compulsory or recommended (code of practice), depending on the particular country.

The feature of these joints corresponding to the type of cladding are specified below. The values specified are general, although it depends on the circumstances. Other more or less precise estimates can be made, according to what is indicated in annex C (information) from the UNE 22203:2011 standard.

o Structural joints: These are consistent with those in the building and have the same width and position. The joint can be sealed with putty up to 2 cm in width. The larger structural joints can be covered with flashing.

o Vertical or expansion joinst: Vertical joints should be arranged approximately every 8 m and in abutments with different materials. The width should be at least 10 mm.

o Union or contour joints: These are the joints between the cladding units, with the contour of the cladding. They should be at least 2 mm wide, although for larger formats, larger values can be reached. Between the pieces, in the horizontal joints, PVC separators or a similar material should be arranged.

MAINTENANCE:

A. CLEANING :

The use of soaps, bleaches or ammonia or other detergents that might damage the stone or the joining material should be avoided.

Acids should never be used.

Try first with less aggressive cleaning methods (tap water).

It is important to choose a cleaning agent that agrees with the nature of the granite.

Cleaning should be done periodically and frequently.

B. INSPECTION :

Keep a permanent eye on the appearance of imperfections in the pieces such as the appearance of humidity.

Check the finish and the joints every 2 years.

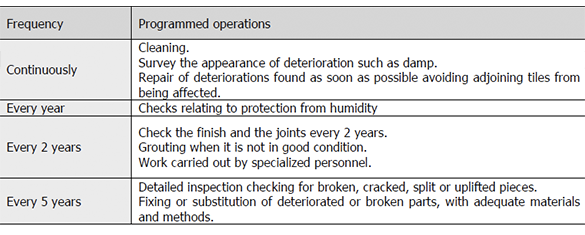

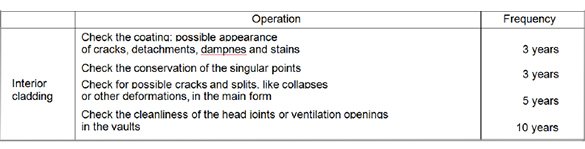

As well as these recommendations the maintenance operations in function with frecuency, bearing in mind those mentioned in CTE-HS1 and in section 6.

Maintenance and conservation, which explains about the maintenance operations in relation with protecition against humidity in the building, which should be carried out regularly for all types of elements.

These inspections are:

Repairs procedures are carried out by specialised personnel.

Repairs on the surface finish when the finish is no longer adequate.

Grounting when it is not in good conditions.

Fixing or substitution of deteriorated or broken parts, with adequate materials and methods.

This will be carried out as soon as possible to avoid affecting adjoining parts.

D. MAINTENANCE PLAN :

Below is a proposed maintenance plan for the granite construction element to which operations may be added when the Project Manager finds it appropiate.