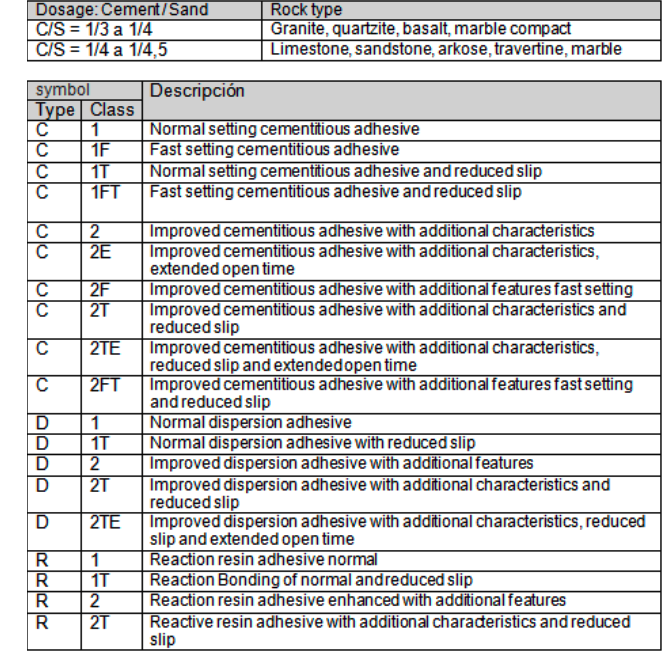

Mix calculations

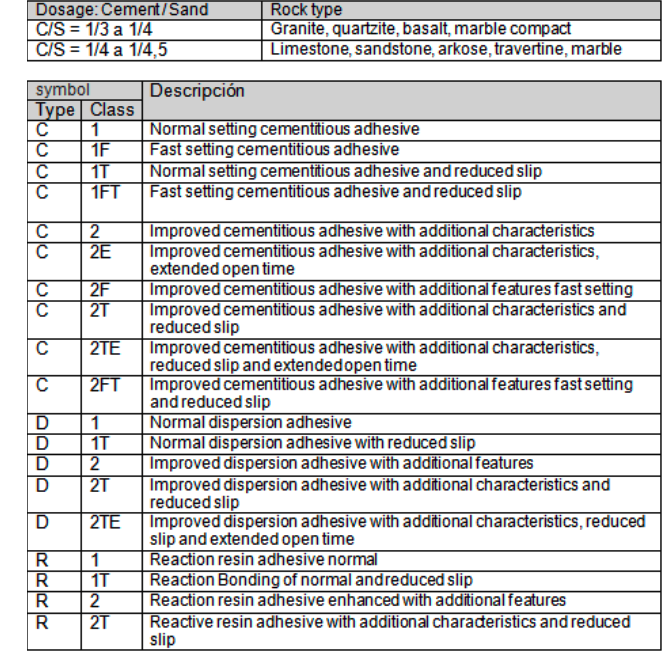

It is used according to recommended by the manufacturer.

Ready to be used directly.

It is used according to recommended by the manufacturer.

According to EN 12004. For example: Mortar 1:4 with 15 mm thickness or thin bed mortar.

high temperature treatment that granitic rocks’ surfaces are subjected in order to obtain a rough, cratered and vitreous surface. The final appearance of the stone is rustic.

to cut the stone’s surface with a diamond teeth disc or steel strapping; the resulting surface is smooth but rough.

It is used according to recommended by the manufacturer.

Ready to be used directly.

It is used according to recommended by the manufacturer.

According to EN 12004. For example: Mortar 1:4 with 15 mm thickness or thin bed mortar.